Have you ever wondered what goes on before I take on a project to repair?

Before I accept an item to fix, I like to have a dialogue with clients about the piece, their goals, and my ability. All of this starts with the Repair Request I have on my Contact Me Page.

So what makes a good repair request? I often have to clarify to potential clients what I need to come up with an accurate estimate to repair the item they’d like me to work on. When you, the client, fills out our contact form, it asks you a series of questions such as:

- How important is matching color or matching fiber content?

- How important is it to you that the repair be machine washable vs. needing to be washed by hand?

- How are you intending to use the item?

- How fragile does the fabric appear?

- How important to you is cost?

- How important is it for you to preserve as much of the textile as possible?

When you answer these questions, they help me understand where your priorities lie in the the repair. Some repairs can be functionally stable, but the color or fiber content might not be the best match. Finding a good color match can be time consuming – are you willing to reimburse me as I purchase different yarns to find the best match for the repair? If you are intending to put the item on display vs use it everyday, that may influence how much of the object needs to be repaired – daily use means I should also prioritize areas I see are going thin, because with more use they may easily become holes soon.

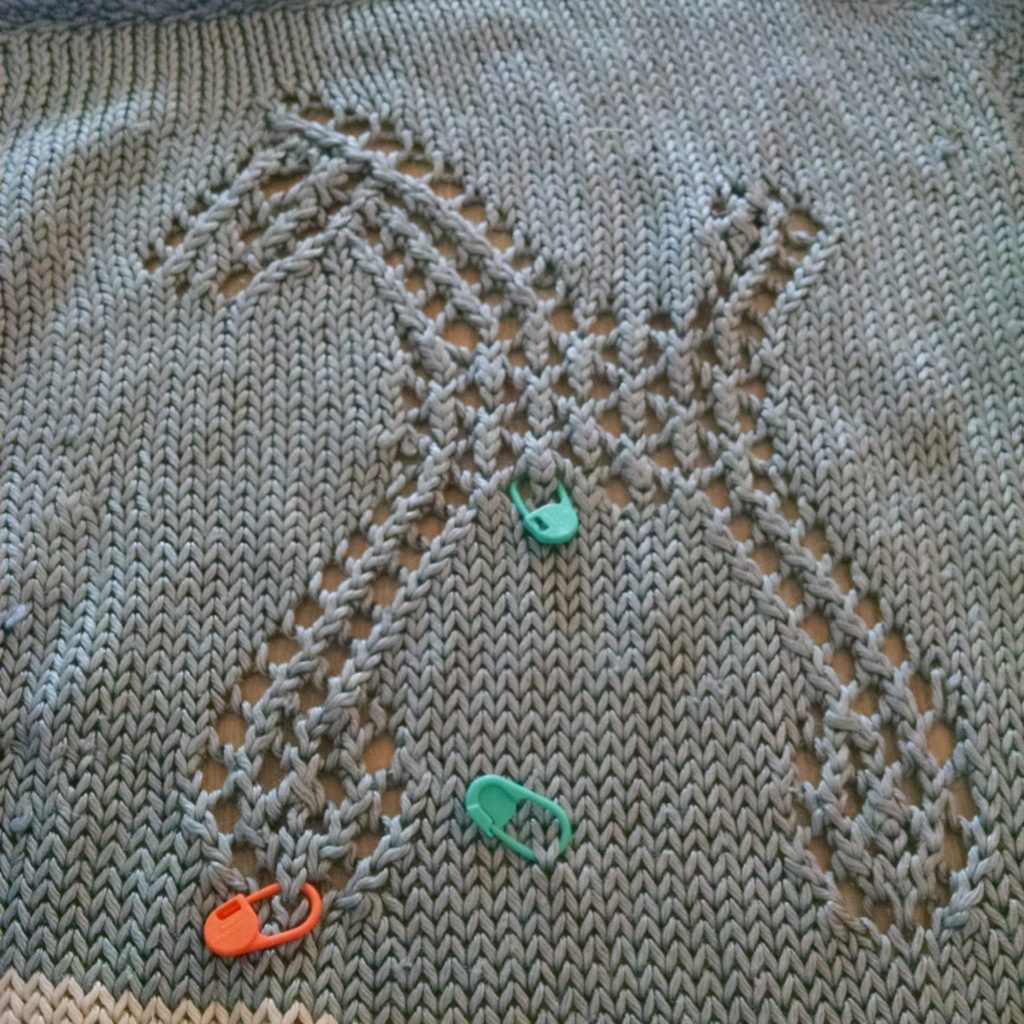

One of the best ways I can get a sense of the item (aside from sending it to me) is to take good photographs. Take a look at the photos below as I show what was really helpful about them.

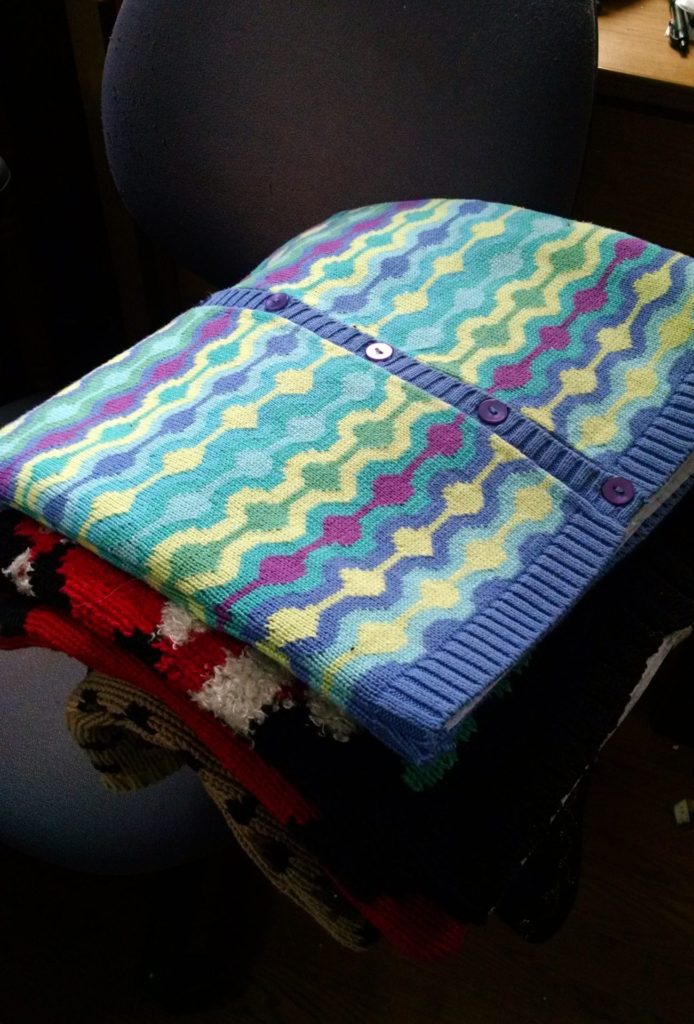

This is a great overall photo of the piece. I can see the pieces of paper that mark the holes, and I know where the holes are in relation to each other. It gives me a sense of the scale of the piece, the overall pattern, and if there are any edgings or other factors I have to take into account while working.

Great photo with a number. The ruler provides a lot of detail for me: I can tell the size of the yarn and how big the hole is. The hole is filling enough of the frame that I can zoom in to look at how the fibers are worn away (ie: frayed, cut, ragged).

Again, the ruler is super helpful. I can also tell the customer had their hands on either side stretching the fabric slightly so I could see everything.

So helpful to have number 3 and 4, which are close together, numbered! In cases where holes are close together, the location of the holes can impact how I approach the repairs, so it’s helpful to see that relational information.

Here the hole was small enough that I couldn’t see it in the overall picture, but can see it here. It was so helpful!

One of the other things this client did was mark each hole with a piece of string. This really saves both of us time. While sometimes people don’t realize there is a hole that I catch, the time it takes for me to find holes that the client already knows about is time I could use on doing repairs. Ultimately it saves us both time, and in the end, the client money.

Got a piece you’d like me to look at? Now that you have a sense of what I’m looking for, head over to Let’s Connect, and get the conversation started.