I’ve been working and plugging away at a number of repair projects, and while I’ve been posting them to Instagram, I thought I’d highlight a few here. We’ve got one crochet piece and one knit piece.

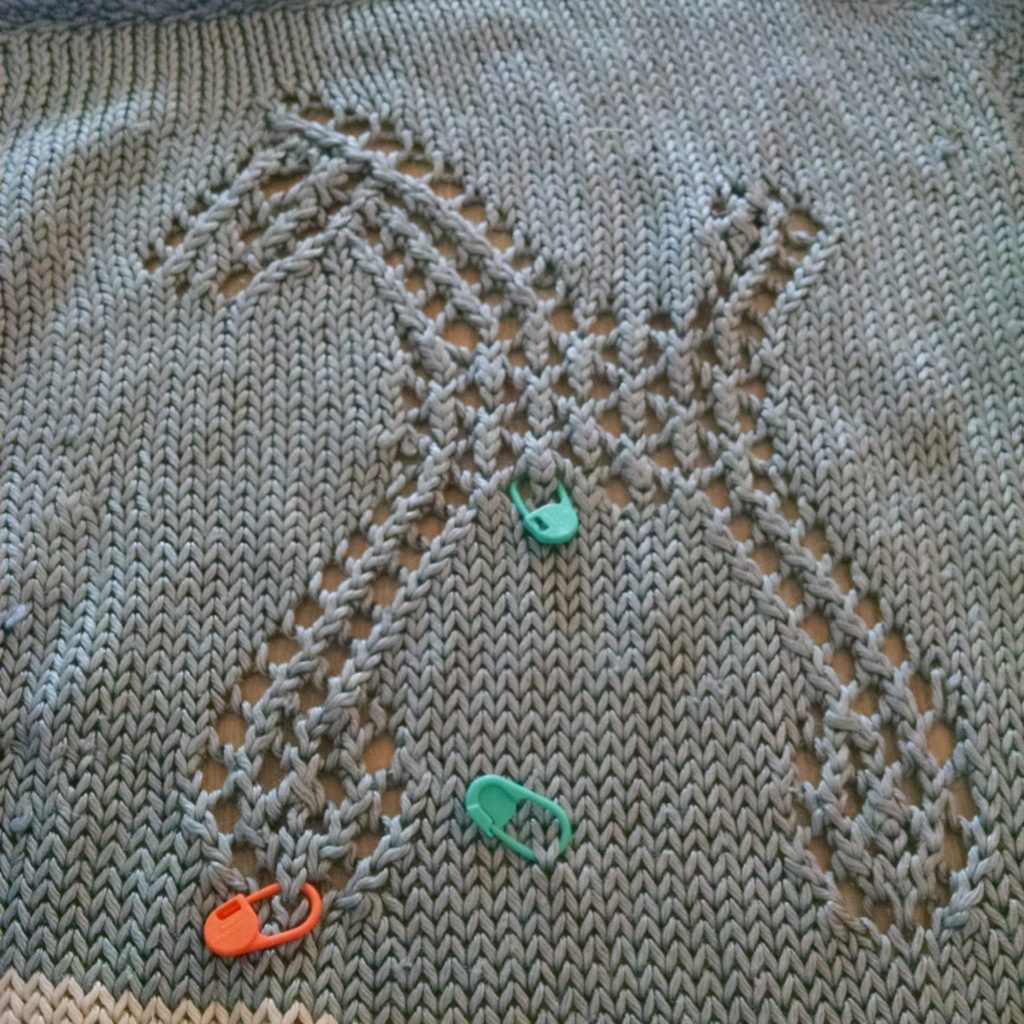

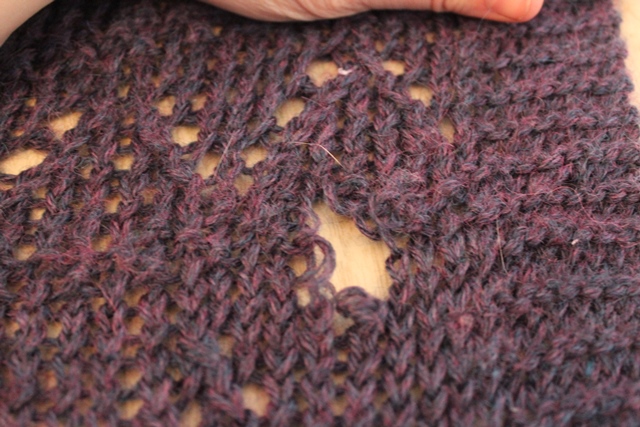

The knit piece features a stocking that was hung over the fireplace with care – but was hung a little too close to the flames!

Not only did the warmth of the fire burn through the stocking, but it melted one of the stocking stuffers to the fabric, causing the bottle to leak all over the fibers. It was a mess!

A side note: this is a really good reason to use wool when making anything that will get anywhere near heat – wool does not melt or burn like acrylic or cotton.

This stocking needed an overhaul – I pulled things out at the ankle and re-knit the foot. I’m pretty pleases with the color matching – not perfect, but pretty close!

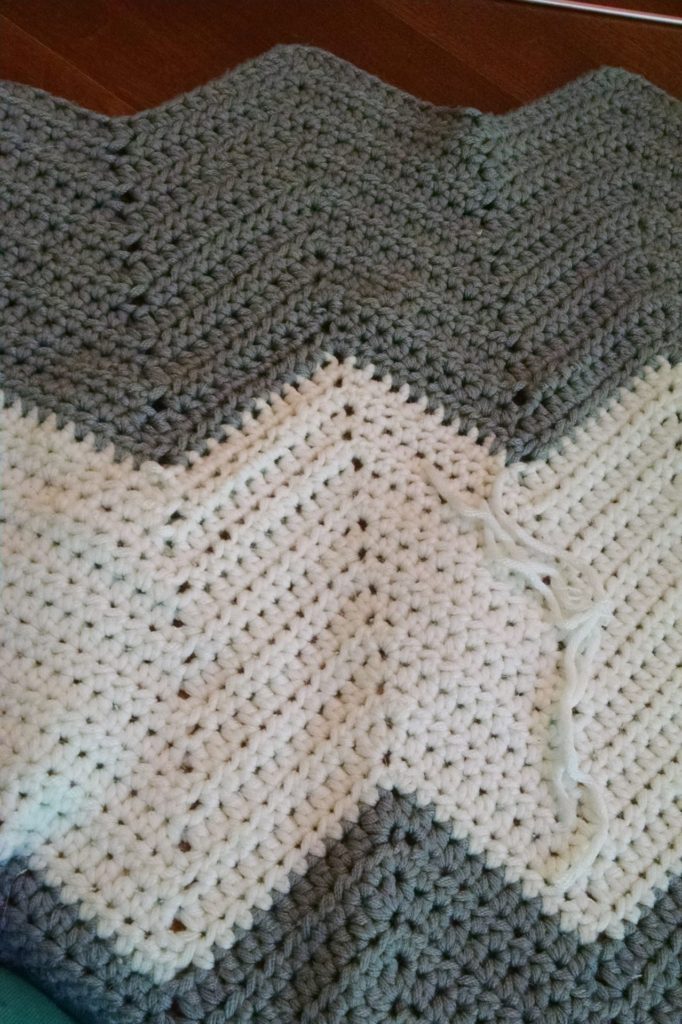

The other project I wrapped up was a crochet afghan that had developed a hole. It was a nice diversion, since the last few repairs I’ve done of crochet afghans have been plain single crochet.

The first step was isolating the crochet stitches that were in danger of unraveling. Because this pattern is a gathered stitch, things are a little more tricky – there isn’t a one-to-one ratio of stitches.

Then there’s the process of re-crocheting the area. I had a choice here: I didn’t have any of the blanket yarn I could harvest, so I could either use a closely matching yarn (which is tough to find with cream colored things), or I could crochet the piece in a slightly tighter gauge so I would have enough yarn to do the repairs (and weave in ends).

This is a strategy that works well over a small area – in this case, this one pinwheel (marked by the teal thread). Over larger areas this would cause the area to pucker.

And that is most of what I’ve been working on! What projects have you gotten off the needles/hook?

![IMG_20170213_145143730[1]](http://www.tinkingturtle.com/wp-content/uploads/2017/02/IMG_20170213_1451437301-e1487108588826-731x1024.jpg)

![IMG_20170213_145612480[1]](http://www.tinkingturtle.com/wp-content/uploads/2017/02/IMG_20170213_1456124801-e1487108484310-755x1024.jpg)

![IMG_20170213_150433116[1]](http://www.tinkingturtle.com/wp-content/uploads/2017/02/IMG_20170213_1504331161-e1487108538166-768x1024.jpg)

![IMG_20170213_150454231[1]](http://www.tinkingturtle.com/wp-content/uploads/2017/02/IMG_20170213_1504542311-1024x576.jpg)

![IMG_20170213_150459010[1]](http://www.tinkingturtle.com/wp-content/uploads/2017/02/IMG_20170213_1504590101-1024x576.jpg)

![IMG_20170213_150719612[1]](http://www.tinkingturtle.com/wp-content/uploads/2017/02/IMG_20170213_1507196121-e1487108649602-768x1024.jpg)

![IMG_20170213_152532582_HDR[1]](http://www.tinkingturtle.com/wp-content/uploads/2017/02/IMG_20170213_152532582_HDR1-e1487108694291-693x1024.jpg)

![IMG_20170213_153216265[1]](http://www.tinkingturtle.com/wp-content/uploads/2017/02/IMG_20170213_1532162651-e1487108729952-760x1024.jpg)

![IMG_20170213_155107783_HDR[1]](http://www.tinkingturtle.com/wp-content/uploads/2017/02/IMG_20170213_155107783_HDR1-e1487108780754-768x1024.jpg)

![IMG_20170213_164514165[1]](http://www.tinkingturtle.com/wp-content/uploads/2017/02/IMG_20170213_1645141651-e1487108843906-799x1024.jpg)

Meanwhile, I’m also looking at the practical part of the project. How damaged is the item? How widespread is the wear? Would attempting to fix the item hurt things further? When I’m looking into this I’m often learning about the history of the item: if it was stored in a place where a lot of sunlight, heat or humidity could get to it, the fibers may be damaged. Are the places where wear is showing from use – such as worn out fingers on mittens, or a handle on a bag becoming worn, or because of a different factor? Often the answers form the type of repairs I can do – mittens that are going to get further wear over each winter are going to receive different treatment than a Christmas stocking that’s taken out once a year.

Meanwhile, I’m also looking at the practical part of the project. How damaged is the item? How widespread is the wear? Would attempting to fix the item hurt things further? When I’m looking into this I’m often learning about the history of the item: if it was stored in a place where a lot of sunlight, heat or humidity could get to it, the fibers may be damaged. Are the places where wear is showing from use – such as worn out fingers on mittens, or a handle on a bag becoming worn, or because of a different factor? Often the answers form the type of repairs I can do – mittens that are going to get further wear over each winter are going to receive different treatment than a Christmas stocking that’s taken out once a year.