It’s getting to be the end of October (where did all the time go?) and that means we’re starting to move into the Holiday season. This is the time of year where the amount of finishing and repair I do nearly triples!

I love doing finishing and repair work – I love being able to help you finish your projects and make them perfect! I love helping you restore older pieces that have gotten loved on a little too much.

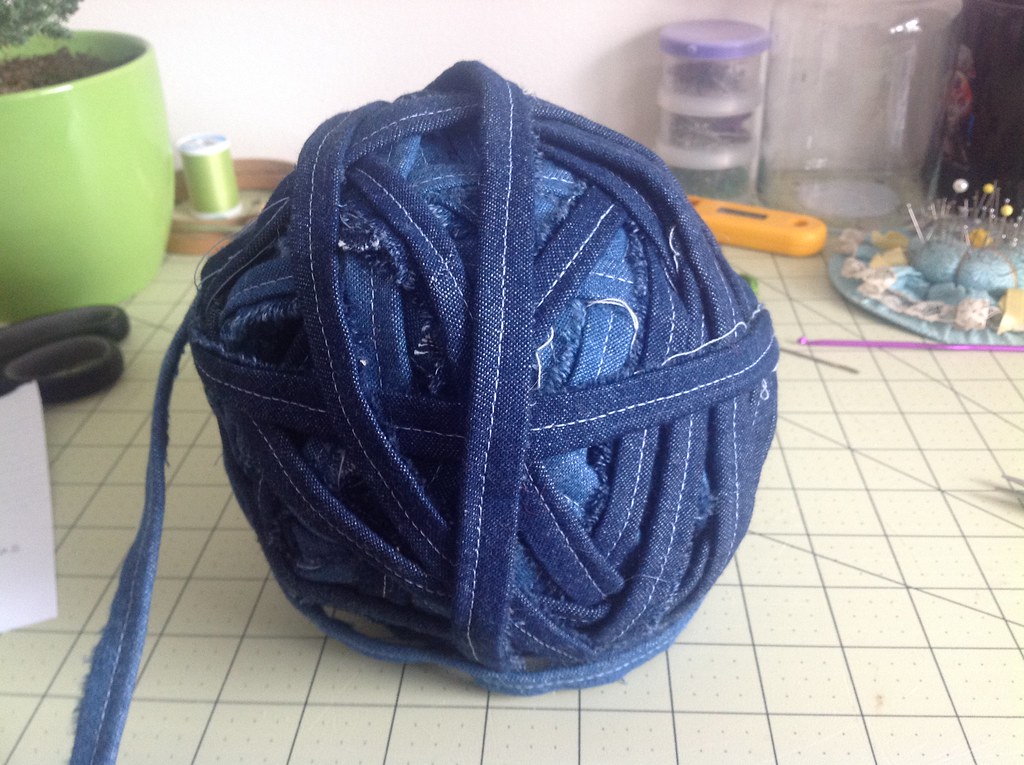

But the reality is that Finishing & Repair are the types of work I can only do so much of in a day before my well runs dry. It’s also time (and very often space) consuming. There’s a reason I get so many different large shawls, blankets and other large items to block! I’m fortunate that Mr. Turtle and I have been able to dedicate a space in the house just for this type of work, and that he’s totally chill with finding a bunch of sweaters and other things drying on the guest bedroom bed.

What Changed?

Quite a few things have changed since I last changed my pricing- nearly two years ago now! And many of these changes have led to me concluding that prices need to increase.

- I moved, and it became more costly for me to drive to my drop-off/pickup locations.

- More individuals have opted to mail, and have me mail back, their items. Postal prices have increased.

- The type of projects I tend to get have become more complicated: most of my customers like to handle the “smaller items” themselves, and send me the more difficult projects.

- My volume of projects has increased! Now, don’t get me wrong – I’m happy about this. BUT! The reality is that knitting, crocheting, seaming, blocking, pinning, etc are all hand and arm heavy activities. I’m relatively young, but I’d hate to find that 5 or 10 years down the road, I’ve given myself a repetitive stress injury. Because of that, I limit the amount of hand-heavy activities I do during a day, and I make sure I have time to stretch in between. This means I have a finite amount of time during the day I can devote to finishing and repair.

- I’ve gotten better. As I practice more and learn more, the quality of my finishing and repair has increased, and I believe that my expertise is worth it!

Frankly, I’ve known I’ve had to raise my prices for nearly 6 months, but the reality of the holidays coming really drove the point home – my prices are not sustainable.

So what does this mean for you, my customer?

- Coming Sunday November 1st, my prices will be increasing on Finishing & Repair work. My hourly rate will increase from $30 to $40. Many of the categories in my Finishing line of services will also change – some won’t change as much as my hourly rate, and some won’t change at all. But most things will be increasing by a little.

- On Monday November 30th, I will no longer be accepting Rush Service. This will continue thru January 1st, and then Rush Service will return. You may still request (and receive!) Express Service. That means if you want to get something finished or repaired before the Christmas Holidays – get it in sooner rather than later.

- There will be a new surcharge for oversized items. Details are still being determined. But the long and short of it is: I have cats. I make sure all my finishing stays in places where it won’t get affected by cats. This is fine for smaller items, but when I need to work on really large things, I have to rearrange my house to create a space where I can work that won’t also have cats laying all over it. This extra effort needs to be taken into account – otherwise I’m going to get frustrated and grumpy every time I go to work on large items. I don’t want that to happen.

- Note: for any of you that have gotten items to be before the November 1st deadline, don’t worry! Your projects will be charged under the old system.

Got questions about the changes? As always, you can leave me a comment, or drop me an email, and I’ll be happy to answer them!

Thank you so much for being loyal customers!